By-products of electrolysis

During water electrolysis, oxygen and heat are generated in addition to hydrogen. Commercial use has the potential to increase the technical and financial efficiency of the system, provided that customers for these media can be found and the operator of the electrolysis system is able to offer an attractive price relative to market prices.

Oxygen

Oxygen from electrolysis is characterised by very high purity, so the main consumers are mainly medical facilities. The industrial use of oxygen is also very wide – covering industries such as the food industry, metal and glass smelting, chemical industry, metal welding and cutting, fish farms, sewage treatment plants as well as many others.

Heat

The commercial use of waste heat from electrolysis systems is conditional on the existence of a potential customer as close as possible to the electrolysis node. Of course, part of the heat released is consumed for the plant’s own needs, i.e. heating of process water. The remaining heat could be supplied to a district heating network or to heat a selected building (office, workshop).

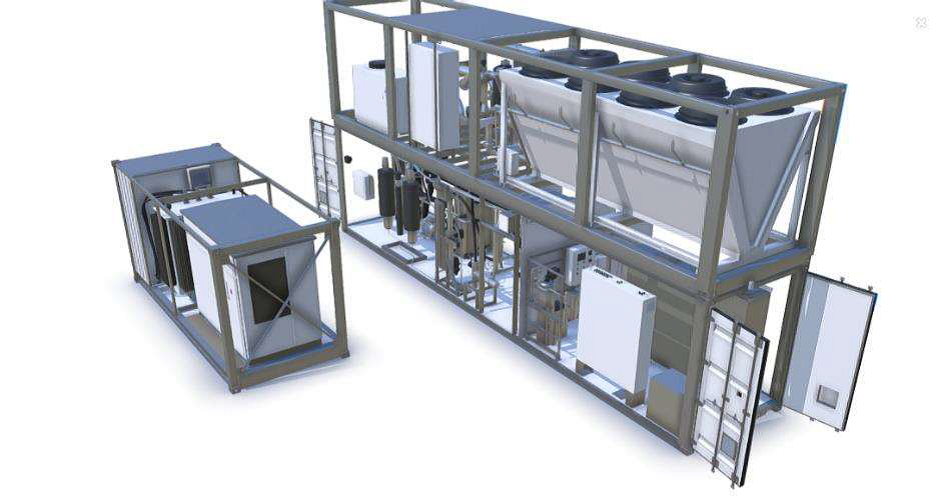

Electrolyser

Based on the type of electrolyte, there are two main types of electrolysers in commercial use: alkaline and polymer membrane electrolysers (PEM). The SOEC electrolyser has a lower availability on the market due to ongoing testing and product commercialisation.

Alkaline electrolyser

Sodium or potassium hydroxide solutions are most commonly used in alkaline electrolysers. The construction of alkaline electrolysers is relatively simple. The system of the device is unipolar and consists of two metal electrodes suspended in an aqueous electrolyte solution. The current flowing through the electrolyser triggers reactions whose products are oxygen released at the anode and hydrogen at the cathode.

PEM electrolyser

Polymer membrane electrolysers (PEMs) are often used in modern technological developments. Electrolysers and PEM fuel cells use an electrolyte made of the solid polymer perfluorosulphonic acid, PFSA, which simultaneously acts as a membrane for proton exchange. PEM electrolysers can be combined into bipolar systems and can operate at high pressures exerted on the ion-exchange membrane.