Example of a hydrogen system – hydrogen production and storage facility

The electrolyser will be powered by its own PV farm and will be equipped with a mine water purification station and a purification and drying unit for the resulting hydrogen.

The components of the hydrogen production and storage hub will be:

- Electrolyser;

- Water treatment plant – as required; The treatment system will therefore consist of a pre-treatment system and a final treatment system, after which the process water reaches demineralised water parameters guaranteeing very high hydrogen purity.

- Hydrogen separator – the hydrogen produced is a two-phase stream (H2 + H2O) in which water vapour, hydrogen and trace amounts of oxygen (in the gas phase) and liquid water coexist. For this reason, and because of the required purity of the hydrogen, the unit separates the water from the fuel;

- Hydrogen purification system – due to the fact that the required hydrogen purity is >99.9%, hydrogen purification is required. As a result, hydrogen purity reaches 99.999%, which is required to power vehicle fuel cells;

- Built-in medium pressure tank (up to 30 bar – depending on the operating pressure of the electrolyser) – buffer between the electrolyser and the hydrogen compressor system.

- Fuel compression system;

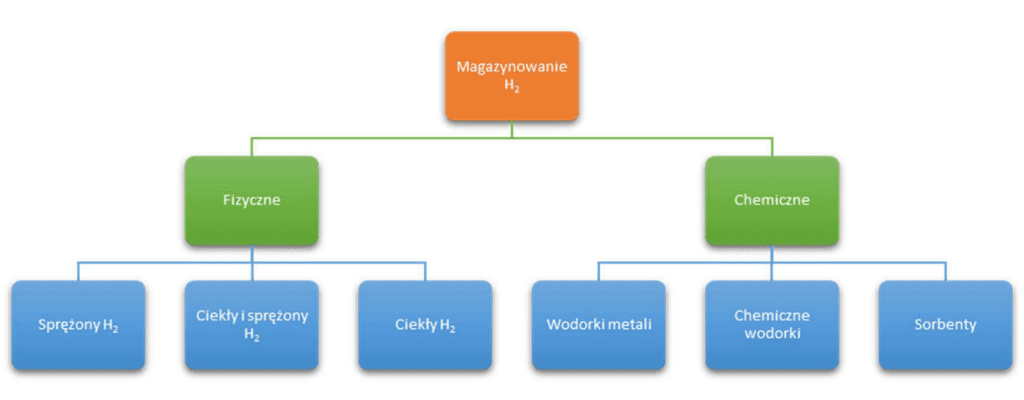

- Hydrogen storage.

Ways of storing hydrogen

Currently, the most widely used method of storing hydrogen is in the form of compressed gas (pressure vessels) or liquid (cryogenic tanks).

Interesting fact: In comparison to hydrogen, liquefying hydrogen requires significantly more energy. However, it has the effect of storing large amounts of fuel in a relatively small volume!

Hydrogen storage facilities

The need for very high pressures of hydrogen for transport applications places high demands on the vessels in which it is stored. There is an international classification of pressure vessels. Different tank types are used for different purposes, mainly due to their cost and mass storage capacity.